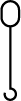

The working load limit (WLL) should be applied in a straight position and overloads should be avoided at all times. In case of chain slings, side loads should be avoided as well. As these materials are not designed for this application, side loads may significantly affect life time in this matter. The working load limit for the product refers to static use. In case of dynamic use (ea breaking, accelerations and / or shock loads), the effective stress on the materials increases significantly which may lead to product failure.

Thorough examination of these materials is required. As these materials in use may be affected by wear, misuse, overloading etc. possibly resulting in deformation and a change in chemical values. If defects are found during this inspection, the materials should be withdrawn from service and additional actions should be determined by a competent person.

If the tag identifying the chain sling and its working load limit is disconnected and the required information is not marked on the sling, the chain sling should be withdrawn from service.

Chain (-slings) and components must be visually inspected every year and be tested before the recommended date on the certificate by an competent person.

Before use of the chain sling it should be ensured that:

Chain slings should be thoroughly cleaned to remove any oil, dirt, rust prior to inspection.

Methods for cleaning to avoid are those using acids, overheating, removal of metal or movement of metal which may cover cracks or surface defects.

In case of lifting chain with multiple legs it is required to replace all chain legs when one of the slings has been disapproved. Components showing any defect should be discarded and replaced in consent. Repair of a lifting item will require a re-inspection.

Lifting equipment should be inspected before taken in use at all times. Prior to the lift, it should be ensured that the load is suitable for the scheduled lift. The area must be cleared and connection of the slings must be checked prior to lifting. Persons who are not involved in the lifting operation should be noticed and aware.

The weight of the load must be known in order to select the proper lifting equipment. Position of the Centre of Gravity of the load should be determined in relation to the possible points of attachment and length of the chain sling. To prevent any tilting or toppling, the following conditions should be met:

It is preferable that the weight distribution should be equal and that the attachment points are above the Centre of Gravity.

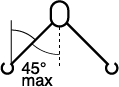

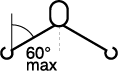

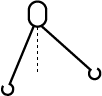

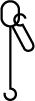

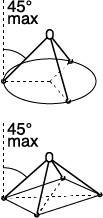

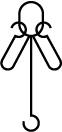

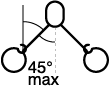

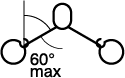

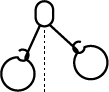

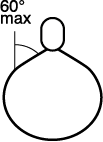

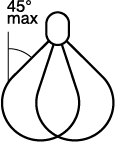

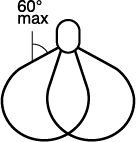

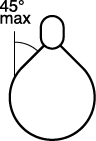

When using two-, three- and four-leg chain slings the attachment points and chain sling configuration should be selected to achieve angles between the chain sling legs and the vertical within the range marked on the chain sling. In any case the angle ß, which is the angle between the chain sling leg and the vertical, should not exceed 60°.

| Safe workloads in tons acc. En 818 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Type | Single | 2-legged | 3- and 4- legged | ||||||

|

|

|

|

|

|

|

|

|

|

| Use condition |

Straight | 0-45° | 45-60° | Asymmetric load |

Single part | 0-45° | 45-60° | Asymmetric load |

Single part |

| Load factor | 1 | 1,4 | 1 | 1 | 1 | 2,1 | 1,5 | 1 | 1 |

| Chain size | |||||||||

| 6 | 1,12 | 1,6 | 1,12 | 1,12 | 1,12 | 2,36 | 1,7 | 1,12 | 1,12 |

| 7 | 1,5 | 2,12 | 1,5 | 1,5 | 1,5 | 3,15 | 2,24 | 1,5 | 1,5 |

| 8 | 2 | 2,8 | 2 | 2 | 2 | 4,25 | 3 | 2 | 2 |

| 10 | 3,15 | 4,25 | 3,15 | 3,15 | 3,15 | 6,7 | 4,75 | 3,15 | 3,15 |

| 13 | 5,3 | 7,5 | 5,3 | 5,3 | 5,3 | 11,2 | 8 | 5,3 | 5,3 |

| 16 | 8 | 11,2 | 8 | 8 | 8 | 17 | 11,8 | 8 | 8 |

| 19 | 11,2 | 16 | 11,2 | 11,2 | 11,2 | 23,6 | 17 | 11,2 | 11,2 |

| 22 | 15 | 21,2 | 15 | 15 | 15 | 31,5 | 22,4 | 15 | 15 |

| 26 | 21,2 | 30 | 21,2 | 21,2 | 21,2 | 45 | 31,5 | 21,2 | 21,2 |

| 32 | 31,5 | 45 | 31,5 | 31,5 | 31,5 | 67 | 47,5 | 31,5 | 31,5 |

| Type | Chockering chain single |

Chockering chain 2-legged |

|||

|---|---|---|---|---|---|

|

|

|

|

|

|

| Use condition |

Straight | 0,45° | 45-60° | Asymmetric load | Single part |

| Load factor | 0,8 | 1,1 | 0,8 | 0,8 | 0,8 |

| Chain size | |||||

| 6 | 0,9 | 1,2 | 0,9 | 0,9 | 0,9 |

| 7 | 1,2 | 1,6 | 1,2 | 1,2 | 1,2 |

| 8 | 1,6 | 2,2 | 1,6 | 1,6 | 1,6 |

| 10 | 2,5 | 3,4 | 2,5 | 2,5 | 2,5 |

| 13 | 4,2 | 5,8 | 4,2 | 4,2 | 4,2 |

| 16 | 6,4 | 8,8 | 6,4 | 6,4 | 6,4 |

| 19 | 8,9 | 12,3 | 8,9 | 8,9 | 8,9 |

| 22 | 12 | 16,5 | 12 | 12 | 12 |

| 26 | 16,9 | 23,3 | 16,9 | 16,9 | 16,9 |

| 32 | 25,2 | 34,6 | 25,2 | 25,2 | 25,2 |

| Type | In basket formation | Chocked endless chain | |||

|---|---|---|---|---|---|

| Single 2-legged combination | Double 4-legged combination | ||||

|

|

|

|

|

|

| Use condition | 0-45° | 45-60° | 0-45° | 45-60° | Straight |

| Load factor | 1,4 | 1 | 2,1 | 1,5 | 1,6 |

| Chain size | |||||

| 6 | 1,6 | 1,12 | 2,36 | 1,7 | 1,8 |

| 7 | 2,12 | 1,5 | 3,15 | 2,24 | 2,5 |

| 8 | 2,8 | 2 | 4,25 | 3 | 3,15 |

| 10 | 4,25 | 3,15 | 6,7 | 4,75 | 5 |

| 13 | 7,5 | 5,3 | 11,2 | 8 | 8,5 |

| 16 | 11,2 | 8 | 17 | 11,8 | 12,5 |

| 19 | 16 | 11,2 | 23,6 | 17 | 18 |

| 22 | 21,2 | 15 | 31,5 | 22,4 | 23,6 |

| 26 | 30 | 21,2 | 45 | 31,5 | 33,5 |

| 32 | 45 | 31,5 | 67 | 47,5 | 50 |

Ensure that the load to be lifted is able to resist both the vertical and horizontal impact forces. The hook connected to the masterlink should be directly above the Centre of Gravity.

When shortening hooks are mounted / being used, the safe working load is the same as by asymmetrical load.

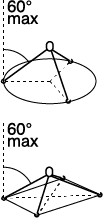

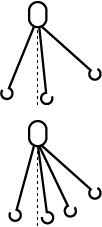

If a multi leg chain sling is not fully used for the purpose for which it has been designed, for example a lift with less legs than the number of legs of the chain assembly, the WLL should be reduced / revised in relation to the markings on the chain sling by applying the relevant factor as given hereunder:

| Types of chain sling |

Number of legs used |

Factor to apply to marked WLL |

|---|---|---|

| Two-leg | 1 | 1/2 |

| Three- and four-leg | 2 | 2/3 |

| Three- and four-leg | 1 | 1/3 |

In any case, the chain sling should have a WLL equal to or greater than the weight to be lifted.

Riggers should be aware of the risks and dangers of shock loading which may break the chain. Lifting operations should always be performed slowly & controlled to the maximum.

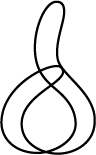

A chain sling is usually attached to the load

with end fittings such as hooks and/or links.

The components should be used for straight in line loading only, this in order to avoid side loads and bending. Suitability of the lifting eyes in relation to the hooks / shackles should be checked prior to lifting. Side- and point loading should be prevented at all times!

The loading can be assumed to be symmetric if all of the following conditions are met:

If one of above parameters is not met than the loading should be considered as asymmetric and the lift should be checked by a competent person to establish the safe rating for the chain sling. Alternatively, in the case of asymmetric loading, the chain sling should be rated at half the marked WLL.

If the load tends to tilt, it should be lowered in order to adjust the rigging set-up (by repositioning the attachment points or by using compatible shortening devices).

Despite the safety factor of 4, never exceed the given working load limit (WLL).

Hands and other body parts should be kept away from the chain to prevent injury. The load should be lifted slowly until the chain is under tension. As soon as the load is slightly raised, a check should be performed to be assured that the load is secured and Lifting operations may never be performed when persons are beneath.

The designated position of the load should be prepared and should be adapted to the weight and dimensions of the load. The area must be cleared of any unnecessary obstacles and people who are not involved. The load should be lowered carefully. The lifting slings should be free and accessible. Before releasing the chain from tension, the load should be checked to ensure that it is properly supported and stable. When finalized the chain sling should be removed by hand and not with the lifting device. The load should not be rolled off the chain as

this may.

When not in use, chain slings should be stored properly. Chain slings and/or assemblies hanging in the main hook should be hanged off in the masterlink (assembly) for safety purposes. Chain slings which will not be in use for a longer period of time should be cleaned and stored dry.

Chain and components may never be affected by welding, heat treating, grinding or any other process which will affect the chemical composition and therefore the strength.

Consult the manufacturer of the chain & components in case exposing to highly concentrated chemicals is applicable.

The rating of lifting accessories in European Standards assumes the absence of exceptionally hazardous conditions. This concerns offshore activities, lifting of persons and lifting of potentially dangerous loads. In such cases the degree of hazard should be assessed by a competent person and the WLL adjusted accordingly.

In case of excessive temperatures we advise you to contact us.